Delivering Consistent Pressure While Minimizing Energy Costs

Nearly all plant air systems have an ever changing fluctuation of demand and air pressure. Peak air demands will draw down pressure in the air system causing dramatic pressure flucuations. These changes inevitably lead to inconsistent production, poor production quality, and wasted energy due to running the system at a higher than necessary pressure.

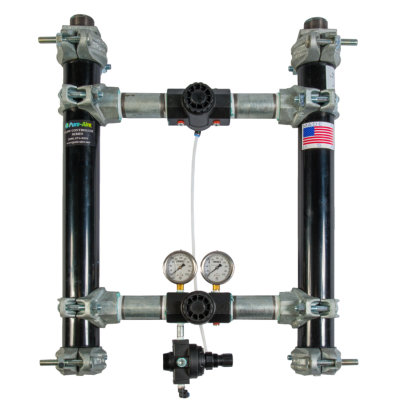

The Pure-Aire SFC System Flow Controller will yield significant air system improvements when installed in conjunction with an adequate supply -side storage tank. This system will enable the supply-side storage tank installed with the compressors to store air for peak demands at an appropriately set control pressure. Additionally, it will deliver the desired plant air pressure setpoint consistently delivering +/- 1% of pressure setpoint. Peak air consumptions will be drawn from storage and less compressor HP will be required for peak events–saving you energy, money, scrap, and downtime.

Benefits and Standard Features

- Flow Rates to 22,000 cfm

- Flow Rates to 22,000 cfm

- Parallel Valve Design to Provide Redundancy

- Stabilize Plant Production Quality and the Compressed Air Pressure +/- 1%

- Stabilize the System Air Pressure in Responses to Dramatic Fluctuations of Demand

- Minimize Waste Through Air Leak Reduction

- Reduces Compressor Energy Consumption

- Improves Compressor Controls and Responses to Changing Air Requirements

- Non-Corrosive Aluminum Piping

- Energy Savings of Approximately 1% for Every 2 psig Change in Pressure

- Single Valve Design Available to Minimize Investment Cost

- Optional Automatic Valve

Energy Savings Realized

Energy savings of thousands of dollars are typically realized with an extremely short payback time frame. Most customers report production savings, which are multiples of the energy savings they realized.